If you’re googling a heat pump tune-up checklist, you’re really asking: “When a tech says they ‘tuned it up,’ what did they actually verify—and what would they catch if they were being meticulous?”

Based on what I’ve seen in real-world service calls, the difference between a solid tune-up and a “15-minute once-over” usually comes down to measured proof: documented temperature splits, static pressure checks, refrigerant diagnostics done the right way, and a careful look at the electrical and airflow details that quietly drive comfort and energy bills. This page gives you a tech-grade inspection checklist built for Longwood heat pumps—plus the why behind each step—so you can confirm your system was genuinely evaluated, spot corner-cutting fast, and know exactly what to expect before you sign off on the service.

TL;DR Quick Answer

Plan on 2 maintenance visits per year: spring (cooling) + fall (heating/heat pump).

Prioritize humidity + airflow checks: drain line flush, pan/float switch, coil cleanliness, and a quick duct/return inspection.

Ask for proof, not promises: request the tech documents temperature split, amps/voltage, and any refrigerant diagnostics readings (when applicable).

Watch for “rush-job” red flags: no written readings, no drain service, and “topping off” refrigerant without explaining airflow/leak risks.

Best outcome: fewer surprise breakdowns, steadier comfort, and lower operating costs—because the system is verified, not guessed at.

Top Takeaways

Measured tune-ups win

Get documented readings. Not guesses.

Airflow + moisture matter most in Longwood

Coils. Drains. Returns/ducts.

Electrical checks prevent “surprise” failures

Capacitors. Contactors. Wiring.

Refrigerant work must be data-driven

No blind “top-offs.” Verify airflow first.

No numbers = no proof

If it’s not written down, it likely wasn’t checked.

A heat pump “tune-up” should be more than a quick rinse and a thermostat check. In Longwood’s heat-and-humidity swings, small issues—restricted airflow, weak capacitors, dirty coils, or a slowly failing contactor—can quietly drive higher bills, uneven comfort, and premature breakdowns. Use the checklist below to confirm your tech inspected the right systems, captured the right readings, and left you with clear documentation.

Longwood heat pump tune-up checklist: what a tech should inspect

Thermostat, controls, and operating mode

Confirm correct system type (heat pump + auxiliary heat) and programming.

Verify cooling and heating calls initiate properly and cycle off cleanly.

Check defrost control function (when applicable) and sensor condition.

Airflow basics (where many problems hide)

Inspect filter condition/fit and return grille obstructions.

Check blower performance: wheel cleanliness, motor condition, mounting, noise/vibration.

Inspect duct connections near the air handler for leaks, kinks, crushed flex, or loose collars.

Take and record static pressure (if your contractor offers it). High static pressure is a major red flag for comfort and efficiency.

Indoor coil, drain, and humidity protection

Inspect evaporator coil cleanliness (as accessible) and signs of ice, corrosion, or oil staining.

Flush and treat the condensate drain line; verify trap/float switch operation (if installed).

Confirm drain pan integrity and check for microbial buildup—critical in humid climates.

Electrical and safety checks (non-negotiable)

Inspect disconnect, wiring, and terminals for overheating/discoloration.

Test capacitor(s), contactor condition, and relay performance.

Measure and record:

Voltage at the unit

Compressor and fan amperage

Verify safety switches and proper grounding.

Outdoor unit condition (coil, fan, cabinet)

Clear debris and confirm proper clearance for airflow.

Inspect condenser coil cleanliness and fin condition (straighten lightly damaged fins if needed).

Check fan blade, motor bearings (if applicable), mounting, and noise.

Confirm cabinet panels are secure to reduce vibration and water intrusion.

Refrigerant diagnostics (done with proof, not guesswork)

A competent tech should evaluate refrigerant performance using measured data, not “it feels cold.”

Record outdoor/indoor temperatures at time of test.

Check refrigerant pressures and calculate superheat/subcooling (method depends on system type).

Look for signs of leakage (oil residue, service valve staining) and note any abnormal readings.

Confirm coil airflow first—poor airflow can mimic refrigerant issues.

Heating-mode specifics (heat pump + backup heat)

Verify reversing valve operation and stable heating performance.

Confirm auxiliary heat engages only when needed (and doesn’t run unnecessarily).

Check defrost cycle behavior and ensure the unit returns to heat properly afterward.

What to do next

If you’re scheduling service, send this checklist to the company before the appointment and ask them to confirm they’ll document the key measurements. It sets expectations upfront—and makes it much easier to compare quotes and workmanship.

“In the service calls I see go sideways, the problem usually isn’t ‘mystery refrigerant’—it’s airflow, moisture, or electrical wear that no one measured. A real Longwood heat pump tune-up leaves documented numbers behind, so you’re deciding with proof, not promises.”

Essential Resources

Verify a Contractor’s License Before You Schedule Service

Use Florida’s official license lookup to confirm the HVAC company (and qualifying license holder) is active and in good standing—an easy way to avoid costly surprises.

URL: https://www.myfloridalicense.com/wl11.asp

Report Unlicensed or Unsafe Work if You Need To

If you suspect unlicensed activity, misleading sales practices, or unsafe workmanship, this is the official DBPR channel to document and escalate concerns.

URL: https://www2.myfloridalicense.com/file-a-complaint/

Check Longwood Permit Requirements When Maintenance Turns Into Major Work

A routine tune-up is one thing—equipment replacement, significant mechanical changes, or certain repairs can trigger permits and inspections. This page helps you stay compliant.

URL: https://www.longwoodfl.org/169/Permitting-and-Inspections

Use Longwood’s Online Permit Portal for Faster Tracking

If a service visit leads to a replacement or larger scope project, this portal makes it easier to review, track, and manage permitting steps without guesswork.

URL: https://ci-longwood-fl.smartgovcommunity.com/Public/Home

Reference Seminole County Building Services for Broader Local Guidance

For county-level building resources that can affect inspections, documentation, and project requirements in the Longwood area, this hub is a practical starting point.

URL: https://www.seminolecountyfl.gov/departments-services/development-services/building/

Understand Baseline HVAC Standards With Florida Building Code Online

When you’re evaluating recommendations (duct changes, equipment replacement, safety upgrades), this code reference helps you understand what “done right” should align with.

URL: https://www.floridabuilding.org/bc/bc_default.aspx

Explore Utility Rebates That Can Offset Upgrade Costs

If your maintenance results point toward replacement, utility incentives can reduce the total cost of a qualifying HVAC upgrade and make the next step more affordable.

URL: https://www.duke-energy.com/Home/Products/Home-Energy-Improvement/HVAC-Replacement?jur=FL01

Supporting Statistics

You breathe mostly indoor air

Americans spend ~90% of their time indoors.

Practical takeaway: HVAC “maintenance” directly affects the air you live in—airflow, drains, and coil cleanliness matter.

Indoor air can be significantly more polluted than outdoor air

Concentrations of some pollutants are often 2–5× higher indoors than typical outdoor levels.

Practical takeaway: A neglected system can keep recirculating contaminants—good maintenance helps reduce that loop.

Air leaks can quietly inflate cooling and heating costs

Air infiltration can account for 30% or more of a home’s heating and cooling costs.

Practical takeaway: A thorough tech should look beyond the equipment and consider leakage/airflow contributors when diagnosing comfort and efficiency issues.

Leaky ducts can materially reduce system efficiency

Leaky ducts can reduce heating and cooling system efficiency by as much as 20%.

Practical takeaway: Even a “simple” tune-up should include at least a basic duct/airflow reality check—because losses may be happening where you can’t see them.

Final Thought & Opinion

A real heat pump tune-up in Longwood should be measured, documented, and preventative—not a quick visual check.

What this page helps you verify

The tech inspected the right components (airflow, electrical, refrigerant diagnostics, drains).

They captured real readings (not “it looks fine”).

You received clear notes on system condition and next steps.

My take from what I’ve repeatedly seen in the field

Most “high bill” and comfort problems aren’t mysterious. They’re usually caused by:

Airflow restrictions (dirty coils, duct issues, high static pressure)

Moisture/drain problems (humidity + clogs + float switch failures)

Electrical wear (capacitors/contactors trending toward failure)

The one rule I’d follow

No documented numbers = no proof.

Ask for the readings, keep them on file, and you’ll make better decisions (and avoid more surprise breakdowns).

FAQ on “HVAC Maintenance in Longwood”

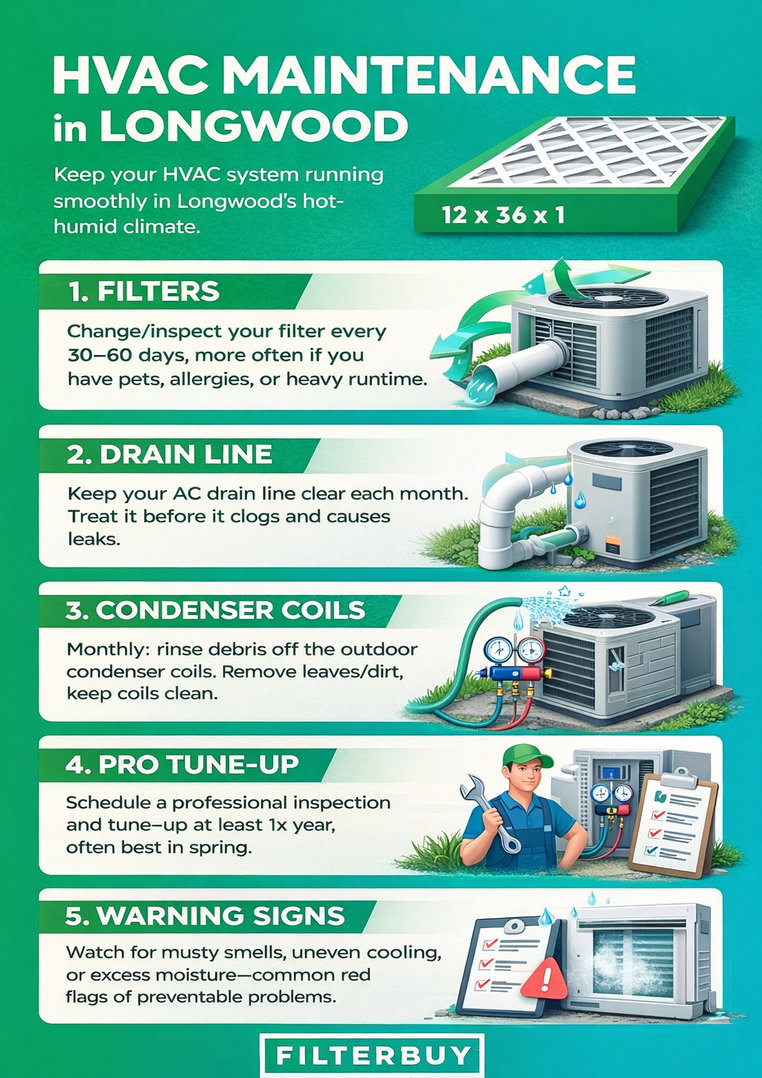

Q: How often do Longwood homes need HVAC maintenance?

A:2× per year (best baseline).

Spring: prep for cooling demand.

Fall: confirm heat pump/heating performance.

Consider 1 extra check if you have pets, allergies, or heavy runtime.

Q: What separates real maintenance from a “quick stop”?

A:Real maintenance includes documented readings.

Temps (performance).

Amps/voltage (electrical health).

Drain/coil notes (humidity + airflow).

No numbers = usually a visual check only.

Q: What gets missed most often that causes breakdowns here?

A:Drain clogs + float switch trips (humidity-driven).

Dirty coils (restricted airflow).

Weak capacitors/contactors (common electrical failures).

Q: Does maintenance actually lower energy costs?

A:Often yes, especially when it fixes:

Airflow restrictions

Dirty coils

Biggest value: fewer surprise outages and longer equipment life.

Q: When should I think about permits in Longwood?

A:Maintenance: usually no permit.

Replacement or major mechanical changes: permits often apply.

Rule of thumb: if equipment is being swapped or reworked, confirm the permit plan upfront.

Learn more about HVAC Care from one of our HVAC solutions branches…

Filterbuy HVAC Solutions - Miami FL - Air Conditioning Service

1300 S Miami Ave Apt 4806 Miami FL 33130

(305) 306-5027

Filterbuy HVAC Solutions - Miami FL - Air Conditioning Service